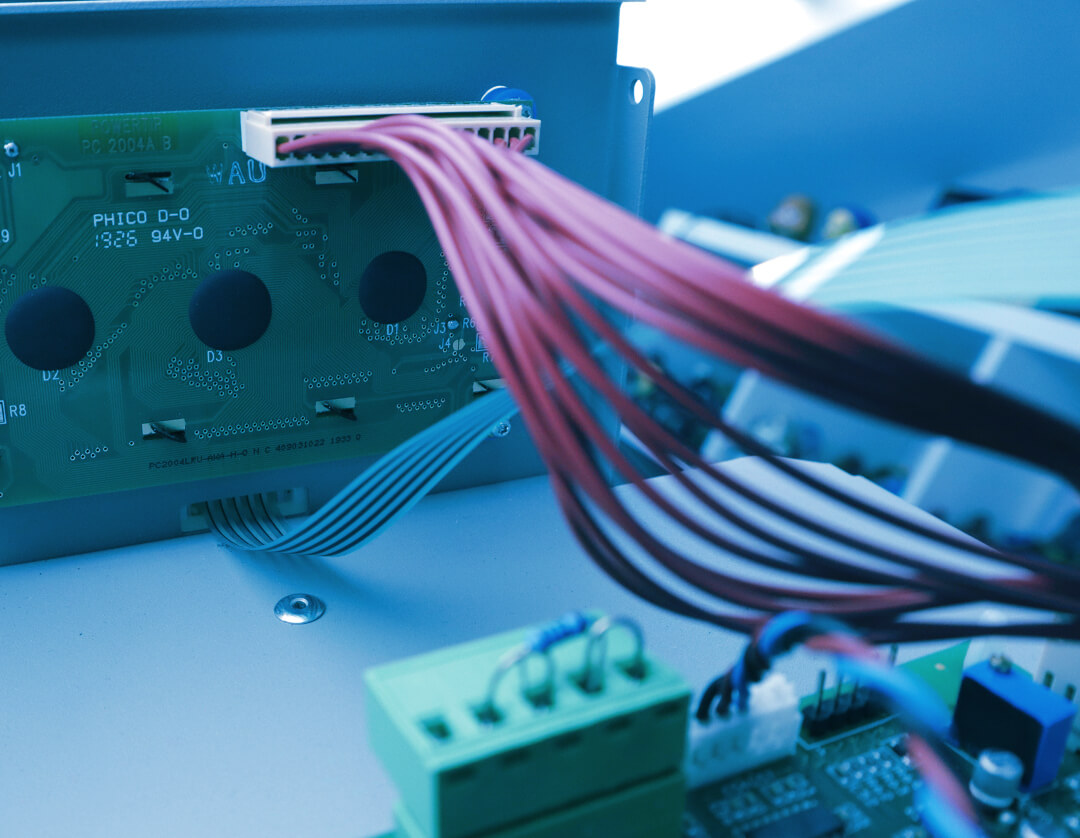

Poseidon Ultrapure Equipment are the final solution to the most demanding customers, those who search the maximum quality on their water and all the information on each stage of the purification procedure. They are conceived for Type II Water Analytic Grade keeping a user friendly philosophy and low maintenance requirements. The sensors and all the alarm systems keep the user informed at all times of the correct state of the equipment, the quality of the water produced and the need of changing any of the filters. The purification stages are the following:

- Pretreatment

- Hyperfiltration through Reverse Osmosis

- Deionisation

- Sterilisation through Ultraviolet Radiation at 254 nm